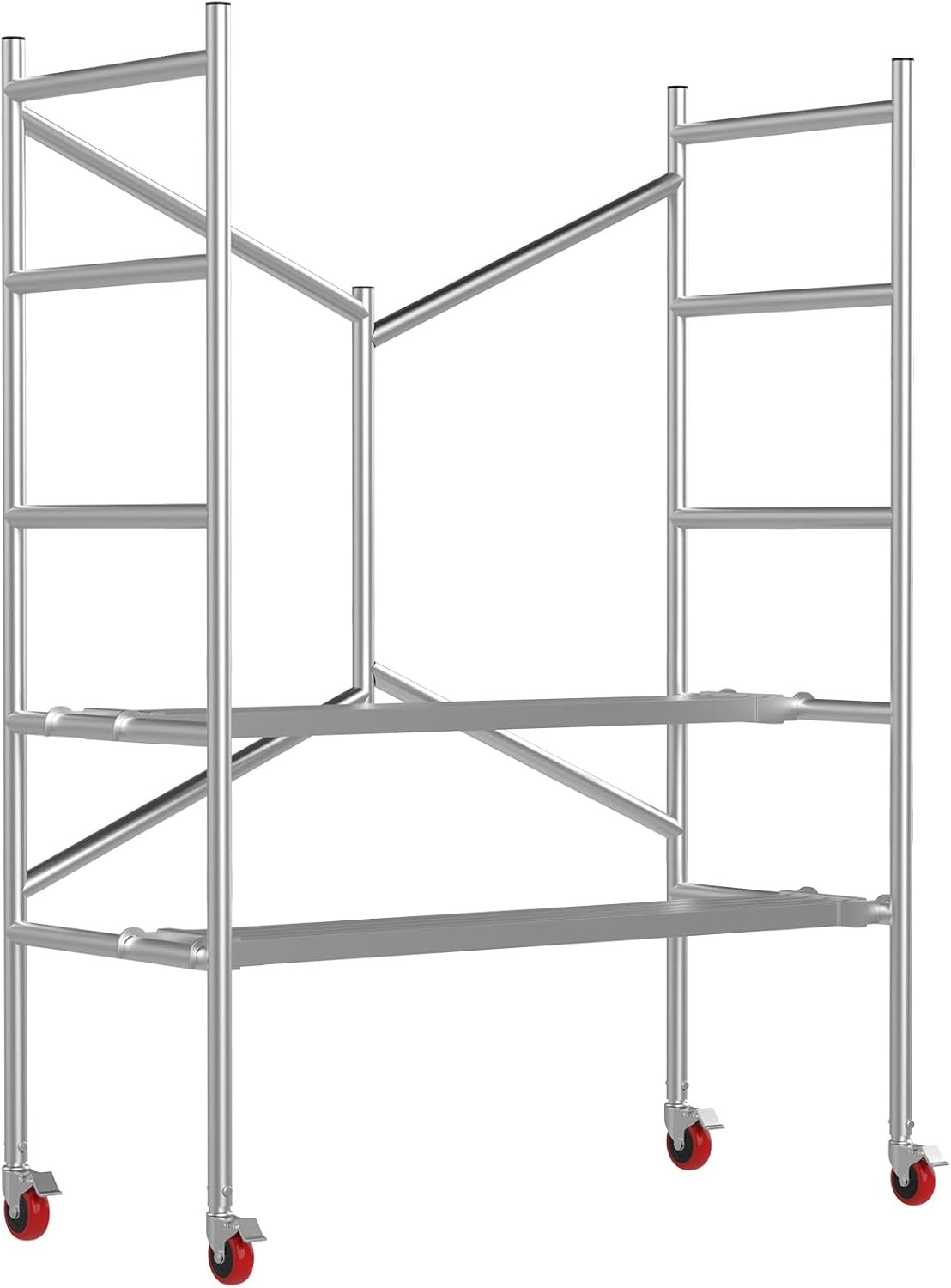

Mobile Scaffolding

Mobile scaffolding is a temporary, highly maneuverable support structure, consisting mainly of vertical posts, crossbars, diagonal braces, working platforms, mobility parts, and safety guards.

It is widely used in construction, equipment maintenance, and related fields. Below is a detailed overview:

1. Key Features

High Mobility & Adaptability: Fitted with swivel casters (some with brakes) at the base, it can be moved by one person—ideal for tasks needing frequent work position shifts. Its modular design allows quick disassembly and reassembly of components (vertical posts, crossbars, etc.) to fit different height and span requirements.

Easy, Efficient Setup: Uses plug-in or bolted joints; no welding or complex tools needed. 1–2 people can assemble a full set in a short time. Disassembled parts stack for storage, saving transport space and enabling short-distance relocation or multi-project reuse.

Secure Structure: Crossbars and diagonal braces form a triangular support system; base rails and counterweights enhance anti-tipping performance. It comes with standard safety features (guardrails, toe boards, access ladders), and some models add anti-fall hooks to meet safety standards.

Flexible Expandability: Various accessories are available—working platforms, ladders, material shelves, or lighting brackets can be added for specific needs. Adjusting base height or adding padding also keeps it stable on uneven ground.

2. Main Categories

By Structure: Divided into portal, wheeled, foldable, and ladder-style mobile scaffolding. Portal types offer strong stability for large-area construction; wheeled types suit local repairs/decoration; foldable types are easy to transport/store (for warehouses/small maintenance); ladder-style types combine ladder and platform functions for tight spaces.

By Rated Load: Classified as light-duty (≤200kg/m²), medium-duty (200–500kg/m²), and heavy-duty (>500kg/m²). Selection depends on the total weight of workers, materials, and tools.

3. Typical Applications

Building Decoration: Used for indoor/outdoor tasks like wall painting, ceiling installation, exterior wall insulation, and glass curtain wall fitting.

Industrial Maintenance: Applied in factory equipment repairs (pipeline welding, machine tool adjustment) and power/communication projects (utility pole upkeep, base station installation).

Commercial & Public Projects: Aids exhibition setup (booth arrangement, backdrop installation) and municipal work (road guardrail repair, streetlight replacement).

Warehousing & Logistics: Serves as a temporary climbing tool for high-shelf goods handling, and can build temporary platforms in truck cabins for easy high-position loading/unloading.

4. Safety Rules

Load Limits: Strictly avoid overloading; working layer load must not exceed the design value, and weight of workers/materials should be evenly distributed.

Movement Rules: Clear working-layer materials and remove temporary fasteners before moving; have someone guide the direction, and never move when people are on the scaffold. Securing Requirements: Lock caster brakes during use; for scaffolds ≥4m high, it should be anchored to nearby stable structures (such as building walls or fixed steel frames) with tie rods—ensure at least one tie point every 2m vertically to prevent lateral sway.

Daily Inspection: Check components before each use: confirm casters roll smoothly and brakes work, inspect poles/braces for cracks or deformation, and ensure guardrails/toe boards are tightly installed. Stop use immediately if any damage is found.

Worker Protection: Require operators to wear anti-slip safety shoes and safety harnesses (for work at heights ≥2m); prohibit standing on guardrails or stacking materials beyond the working layer’s edge to avoid falling risks.

5. Maintenance & Storage Tips

Post-Use Cleaning: Remove mud, paint, or debris from components with a brush or water; avoid using corrosive cleaners to prevent rust on metal parts.

Rust & Damage Handling: Sand and repaint rusted areas promptly; replace severely bent, cracked, or worn parts (such as deformed poles or broken casters) instead of repairing them to ensure structural safety.

Storage Conditions: Store disassembled components in a dry, well-ventilated area; place metal parts on pallets (not directly on the ground) to avoid moisture damage, and cover with waterproof cloth if stored outdoors temporarily.

Inventory Management: Label components by type and size (e.g., "1.2m crossbar" "portal frame") to speed up assembly later; regularly count inventory to avoid missing parts during project setup.

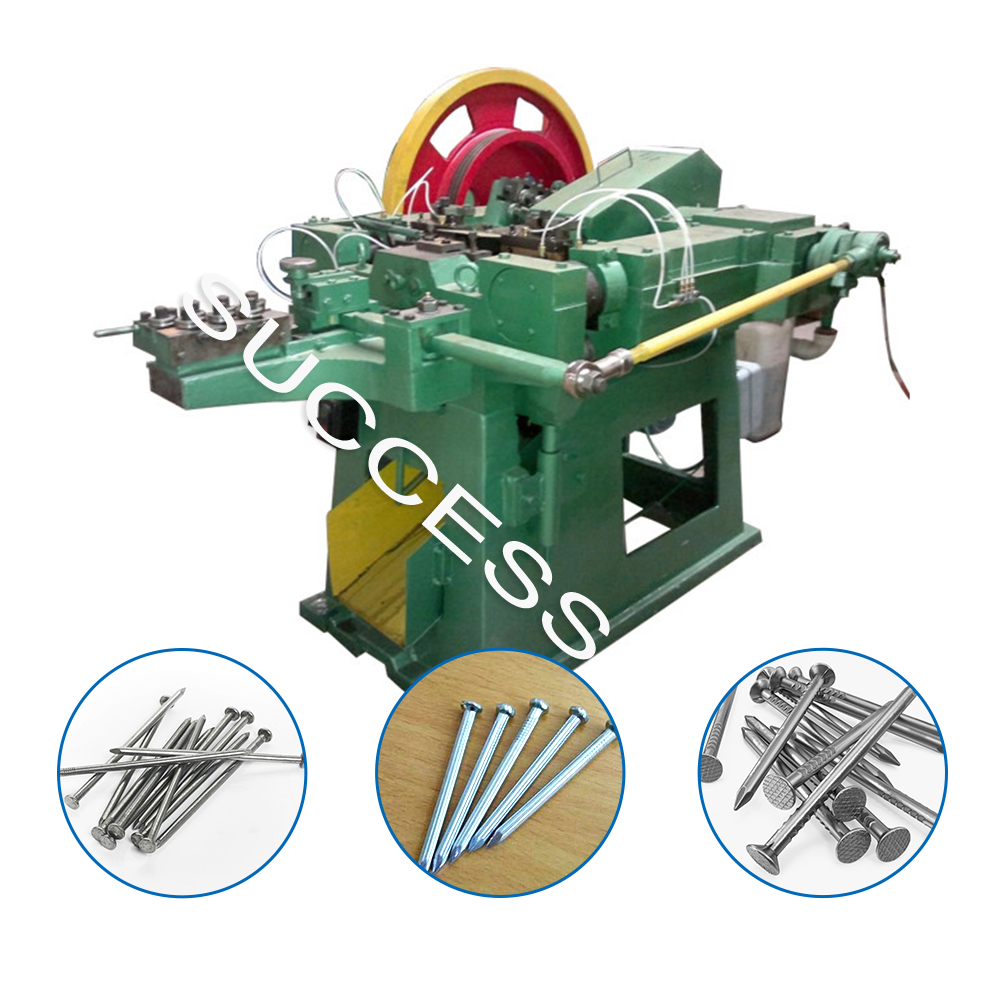

SUCCESS HARDWARE PTE LTD

SUCCESS HARDWARE PTE LTD